Hook-and-loop fasteners, also known as touch fasteners or by the genericized trademark Velcro, are a versatile method of temporarily fastening two surfaces together. Invented by Swiss engineer George de Mestral in 1941, these fasteners have revolutionized various industries and everyday life.

Composition and Mechanism

Hook-and-loop fasteners consist of two components:

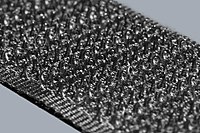

- A strip with tiny hooks

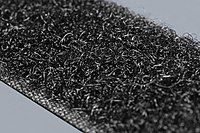

- A strip with smaller loops

When pressed together, the hooks catch in the loops, creating a temporary bond. Separating the strips produces a distinctive ripping sound.

History and Development

The invention was inspired by nature when de Mestral noticed burdock burrs sticking to his clothes and dog’s fur after a hunting trip. He examined the burrs under a microscope and observed their hook-like structure[1].

Key developments in the history of hook-and-loop fasteners include:

- 1941: Concept conceived by George de Mestral

- 1951: Patent submitted in Switzerland

- 1955: Patent granted

- 1957: Expansion to the United States

- 1958: First public mention in Sylvia Porter’s column

- 1959: Display at a fashion show in New York

- 1960s: Adoption by NASA for space suits

- Mid-1960s: Use in fashion by designers like Pierre Cardin

- 1978: Expiration of de Mestral’s patent, leading to imitations

Strength and Durability

The strength of hook-and-loop fasteners depends on several factors:

- Embedding of hooks in loops

- Surface area in contact

- Nature of the force applied

Fasteners made with Teflon loops, polyester hooks, and glass backing are used in aerospace applications. The bond is particularly strong when used to fasten rigid surfaces.

Advantages and Disadvantages

Advantages:

- Safe and maintenance-free

- Minimal decline in effectiveness after multiple uses

- Audible closure (can deter pickpockets)

Disadvantages:

- Accumulates hair, dust, and fur

- Loops can become elongated or broken

- May damage clothing when removed

- Absorbs moisture and perspiration

Applications

Hook-and-loop fasteners are used in various fields:

| Field | Applications |

|---|---|

| Clothing | Replaces buttons and zippers, used in adaptive clothing |

| Medical | Temporary fascia expander prostheses, artificial heart surgery |

| Automotive | Headliners, floor mats, speaker covers |

| Home | Drapery pleating, carpet installation, upholstery |

| Sports | Surfboard leashes, orthopedic braces, tag rugby, flag football |

| Aerospace | Astronaut suits, equipment anchoring in space |

| Music | Attaching guitar pedals to pedalboards |

NASA has made extensive use of hook-and-loop fasteners in space missions, including the Space Shuttle and International Space Station.

Variations and Standards

- Slidingly Engaging Fastener: Addresses problems with common hook-and-loop fasteners

- Heavy-duty variants: Feature mushroom-shaped stems for stronger bonds

- Silent versions: Known as Quiet Closures

Standards for testing hook-and-loop fasteners include:

- ASTM D5169-98 (2010)

- ASTM D5170-98 (2010)

- ASTM D2050-11

Cultural Impact

Hook-and-loop fasteners have made their way into popular culture:

- Featured in TV shows like Star Trek and Late Night with David Letterman

- Mentioned in films such as Men in Black and Garden State

- Inspired recreational activities like Velcro jumping

- Used in April Fools’ Day jokes by companies like Lexus

In conclusion, hook-and-loop fasteners have become an integral part of modern life, finding applications in diverse fields from space exploration to everyday clothing. Their simple yet effective design continues to inspire new uses and variations, making them a truly revolutionary invention.

[glossary_wikipedia]Hook-and-loop fasteners, hook-and-pile fasteners or touch fasteners (often referred to by the genericized trademark velcro, which was the original name it was given by the inventor), are a method for allowing two surfaces to be repeatedly fastened and unfastened, useful for clothing or other purposes. The fastener consists of two components: typically, two lineal fabric strips (or, alternatively, smaller segments) which are attached (sewn or otherwise adhered) to the opposing surfaces designed to be fastened together. The first component features tiny hooks and the second component features smaller loops; When the two are pressed together, the hooks catch in the loops and the two pieces fasten or bind temporarily. When separated, which can be done by pulling or peeling the two surfaces apart, the strips make a distinctive ripping sound.